The Architecture of Sensor Intelligence

Advanced multi-modal sensing that turns surfaces into high-resolution data sources.

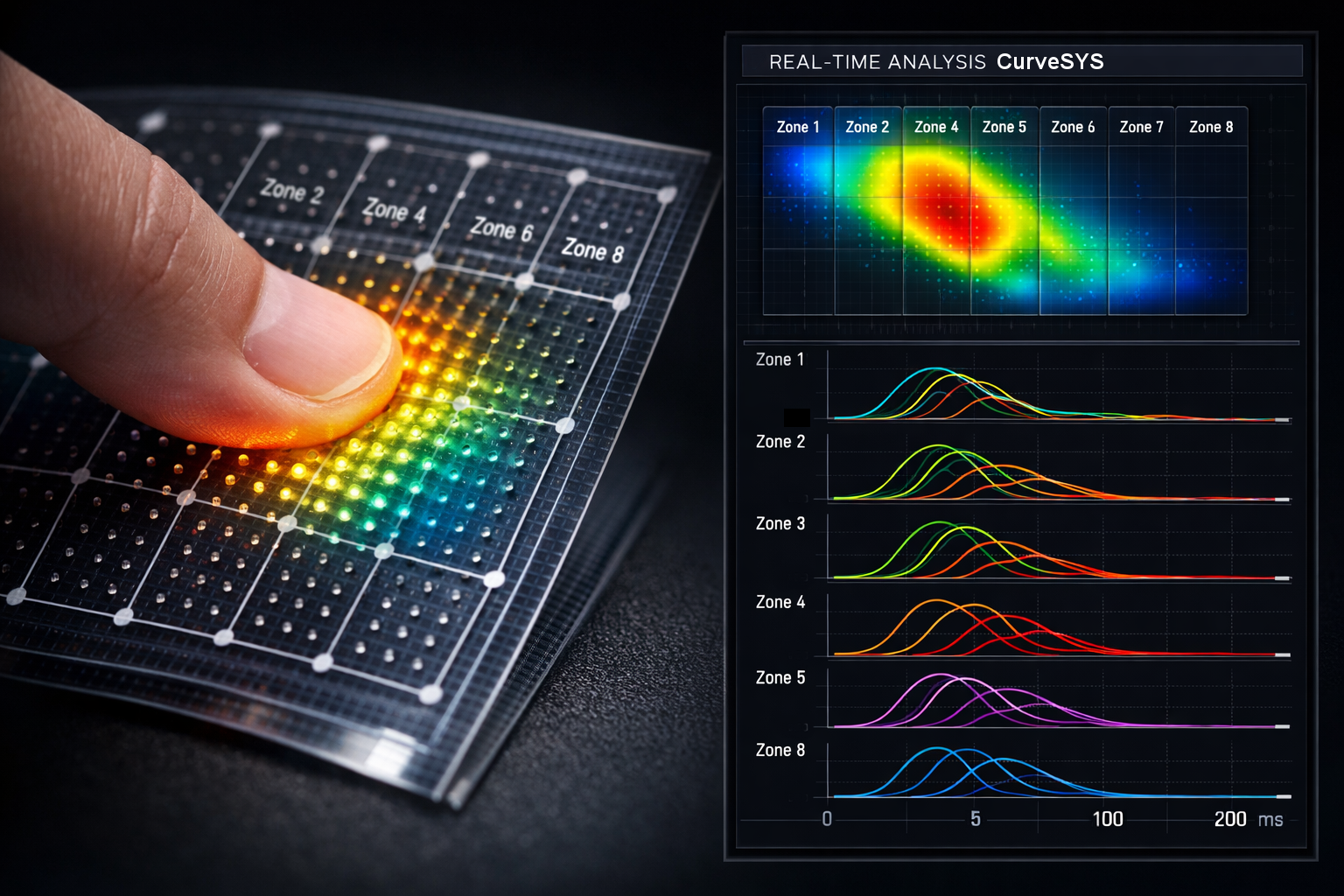

High-Definition Surface Intelligence

Multimodal data capture for unprecedented material insight.

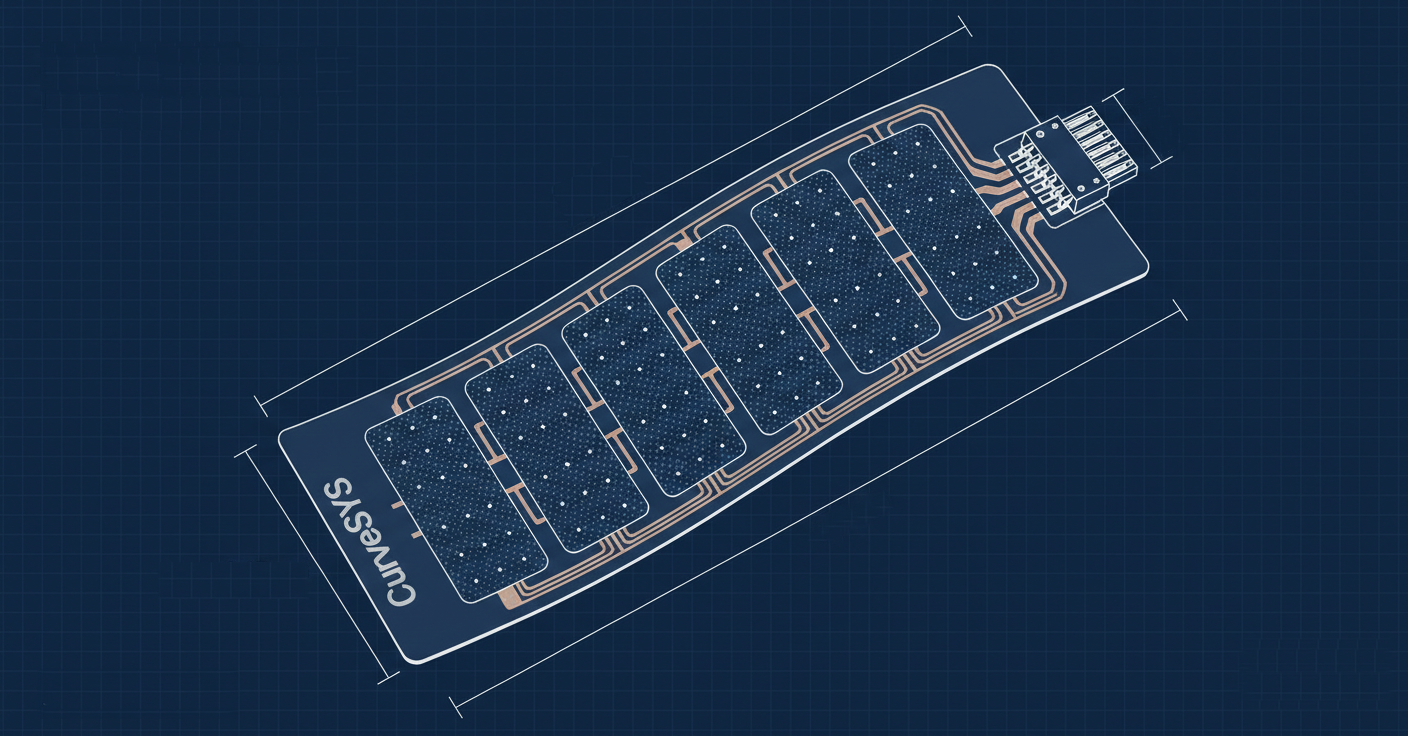

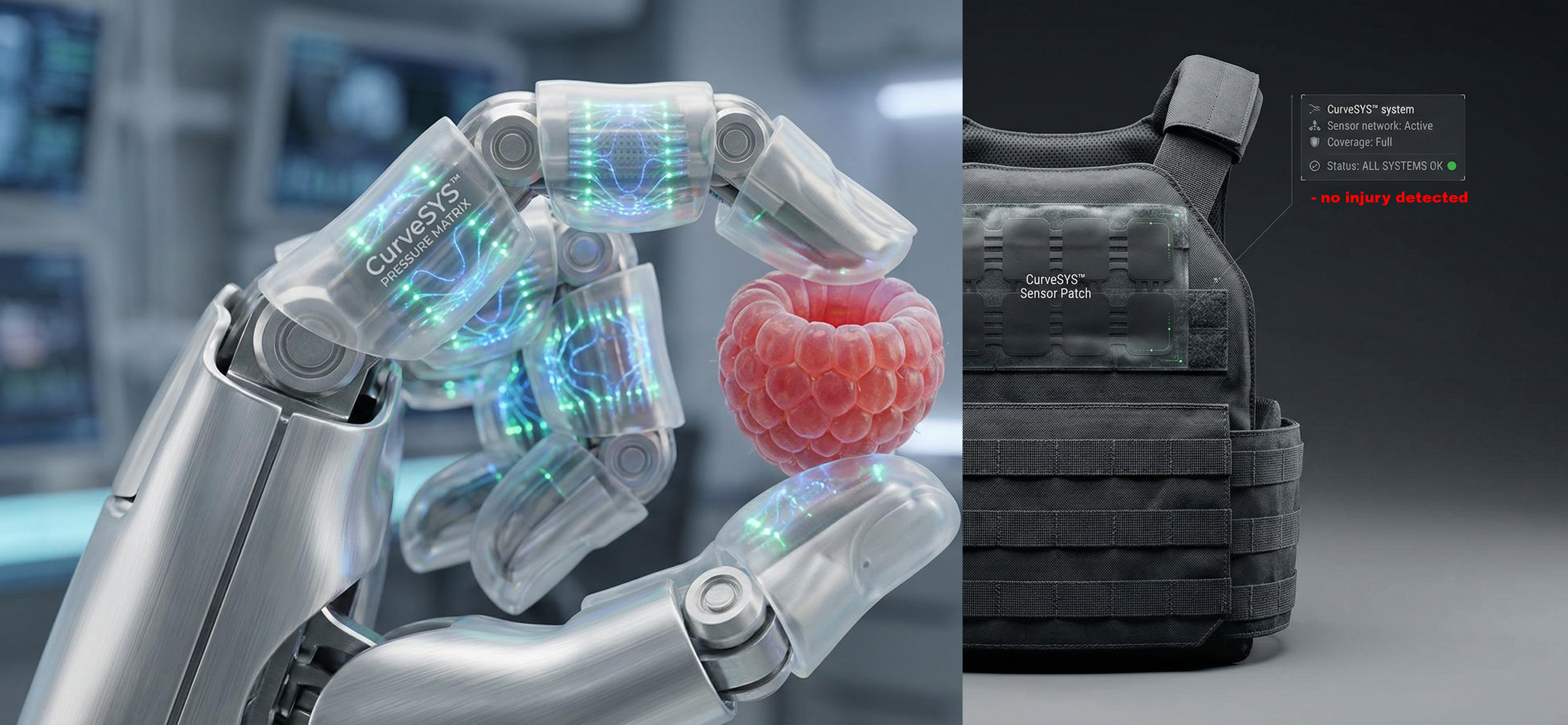

Our patented sensor architecture allows for the simultaneous tracking of multiple physical variables across a single, deformable surface. As visualized in our multi-zone analysis, CurveSYS™ technology maps both force and temperature changes with surgical precision. By dividing the sensing area into intelligent zones, we provide granular data that traditional sensors simply cannot capture—turning any material into a high-performance data source.

Denis Guezelocak, CEO

The Next-Generation Sensing

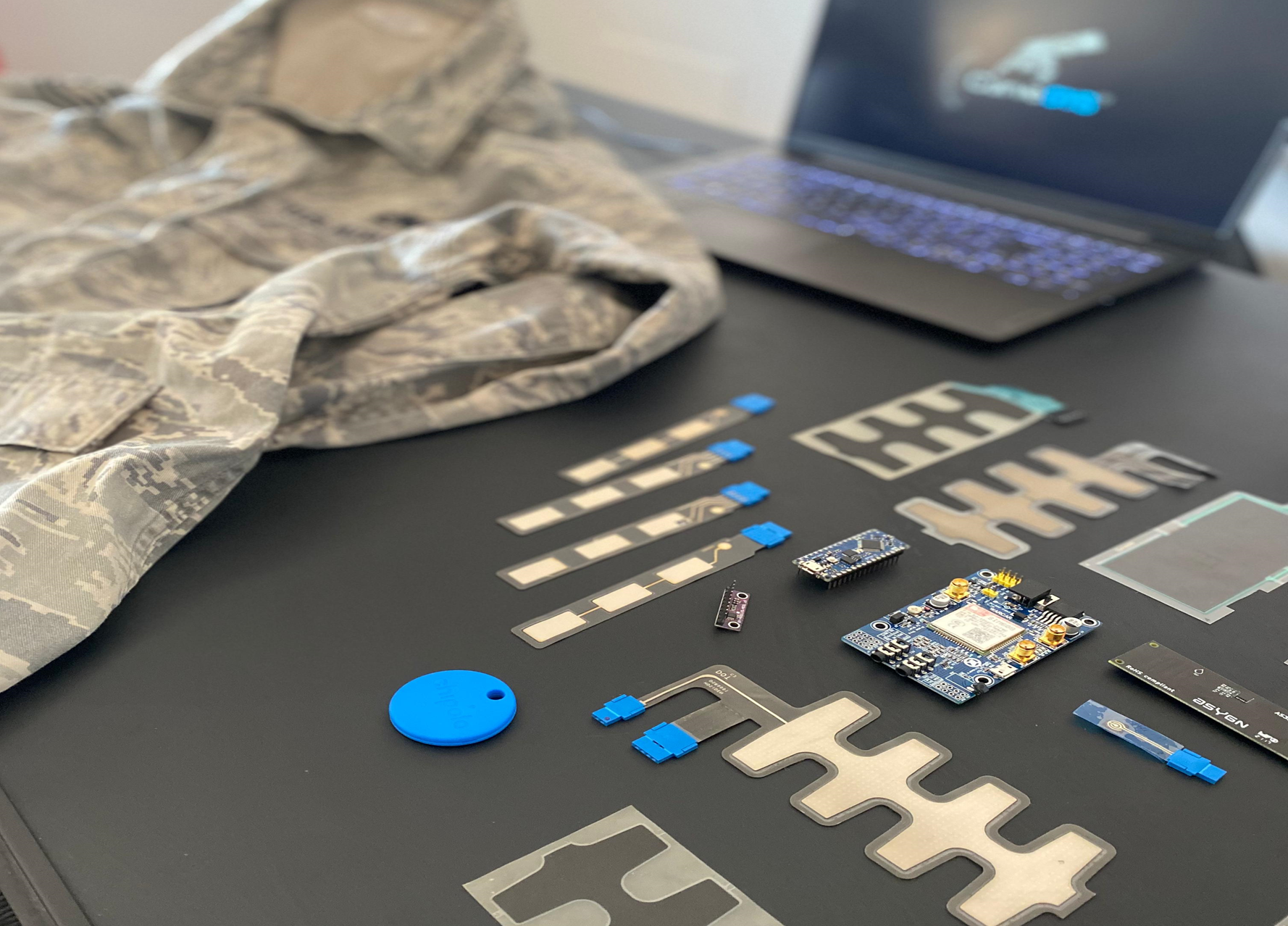

Built on advanced material science, our sensors combine

mechanical resilience with precise, energy-efficient signal acquisition. Engineered for long-term reliability in harsh conditions, CurveSYS™ enables surfaces to sense interaction, load, and physical events in real time. Designed for demanding environments, CurveSYS™ sensors deliver reliable, high-performance data capture with low power consumption. The result is scalable, production-ready sensor intelligence for next-generation systems and applications.

What makes CurveSYS™ different

CurveSYS develops flexible sensor systems that transform mechanical interaction into meaningful data. Our technology enables the detection of pressure, deformation and structural events across complex surfaces – in real time and under harsh conditions and on curved surfaces.

Precision

Dynamic force mapping for delicate object manipulation.

Real-Time Haptics

Instant feedback loops for advanced robotic dexterity.

Life-Saving Diagnostics

Instant ‚ALL SYSTEMS OK‘ or ‚INJURY‘ status alerts for rapid medical response

Next-Gen Sensor

Protecting People. Communicating Rapidly.

At CurveSYS, we develop Next-Gen Sensor Intelligence for a safer tomorrow. We turn surfaces and fabrics into smart systems that can sense the environment and the human body.

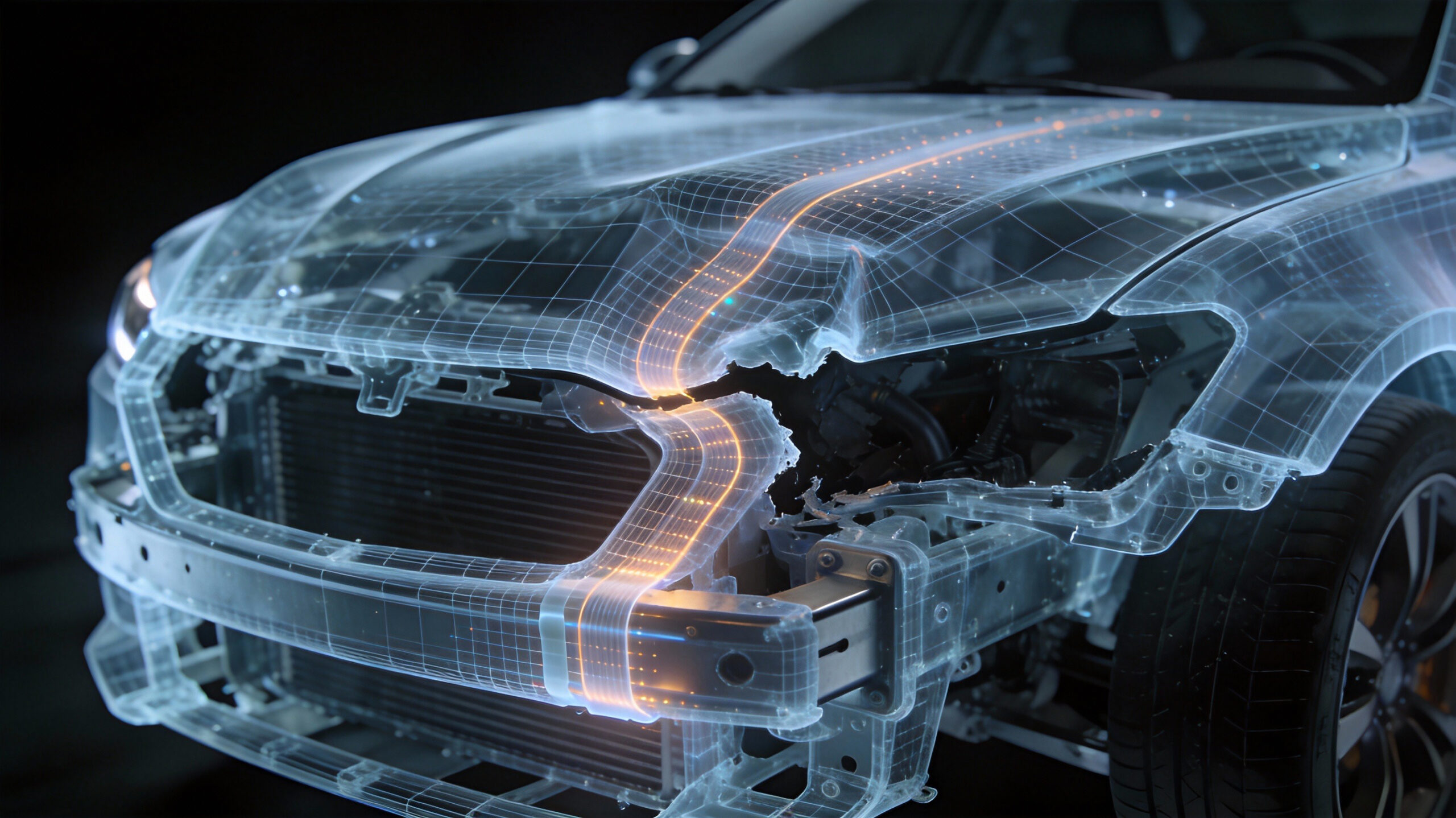

Beyond the Impact:

Intelligent Collision Awareness.

And we turn vehicle structures into sensitive digital nervous systems. Our integrated sensor technology monitors structural integrity in real-time, ensuring that every impact is detected, analyzed, and communicated instantly. In the critical seconds after an accident, data saves lives. We provide the rapid communication link needed to alert emergency services and provide precise diagnostic data before the first responder even arrives.

Because when every millisecond counts, your vehicle shouldn’t just crash — it should react.

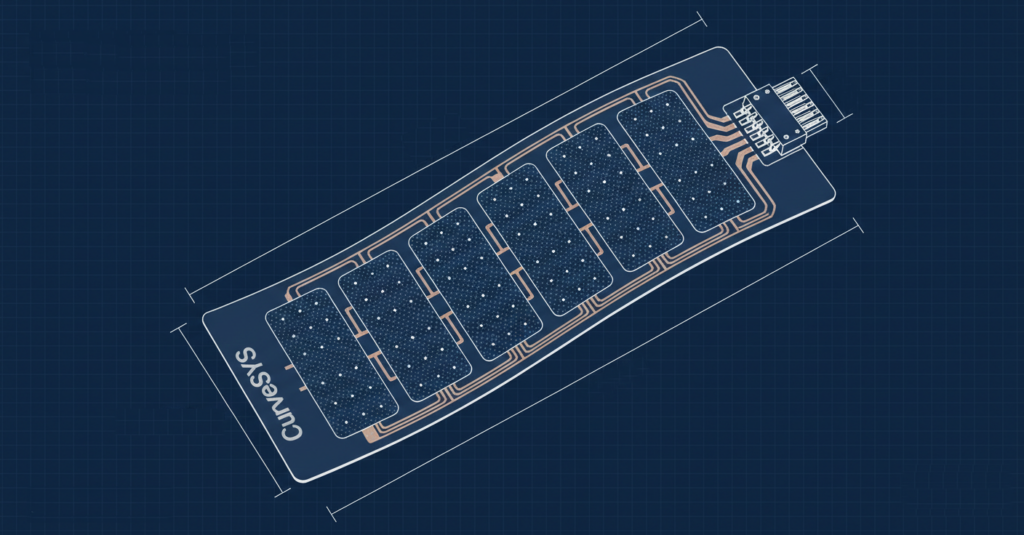

The Sensor Architecture

..

CurveSYS™ Technology – Key USPs

True Deformation Intelligence: CurveSYS™ sensors do not just detect pressure — they understand deformation. By combining elastic sensor layers with defined spacer structures, CurveSYS™ captures bending, compression, shear, and impact in a single, robust architecture..

CurveSYS™ | A New Standard in Sensing

Our technology doesn’t just collect data; it redefines structural intelligence.

Real-Time Authority

Mission-Ready Reliability

Multi-Functional Intelligence: CurveSYS sensors are not just pressure-sensitive. They can be equipped with heating capabilities and environmental sensing, creating a truly multi-modal interface in a single layer.

Mission-Ready Reliability: Designed for critical applications in Defense and Automotive, our systems are „battle-tested“ to provide accurate data under extreme conditions and mechanical impact.

Designed to Bend – Not to Break

Inside the Core-Technology

Our ‘Life Saving Sensor’ technology isn’t just a concept—it’s a patented reality This video breaks down the patented principle that makes CurveSYS unique. Learn how our robust, ultra-thin films integrate into protective gear to monitor physical strain and environmental threats in real-time.

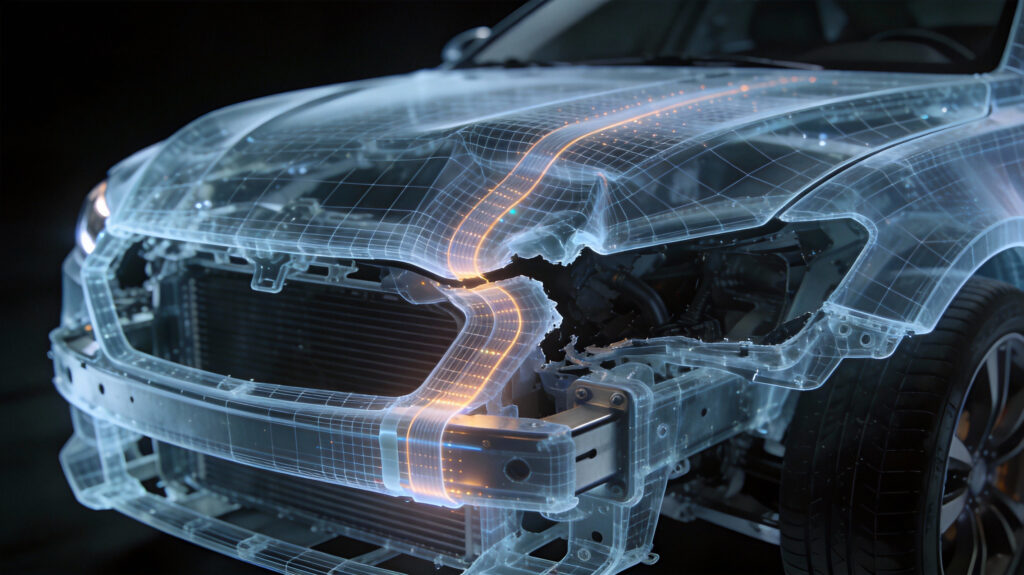

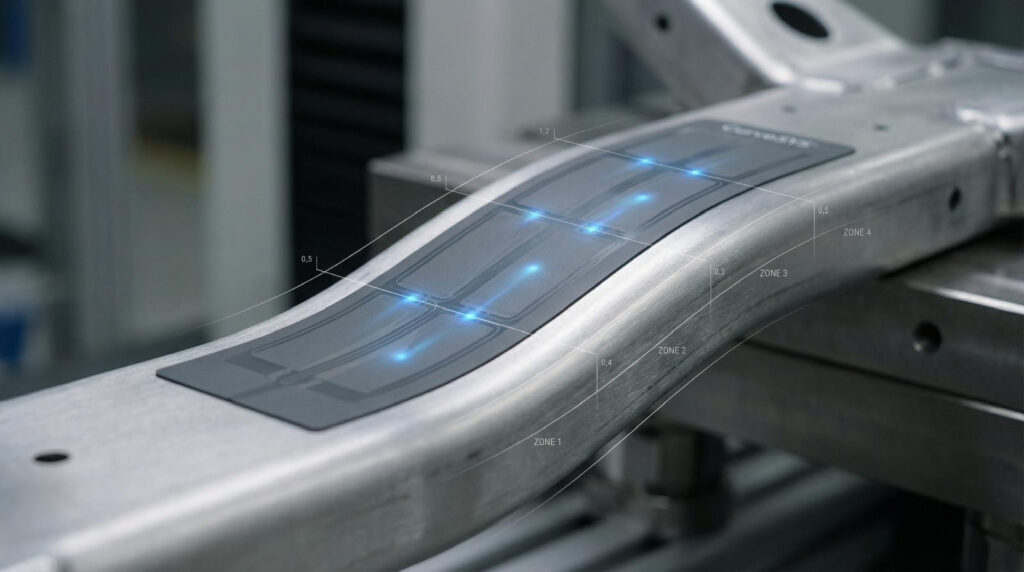

The Sentient Body – Revolutionizing Vehicle Safety

CurveSYS presents a new era of integrated safety: the „Sentient Body.“ This video demonstrates the technological transition from a purely passive vehicle structure to an intelligent, „sensing“ system that transforms mechanical stress into valuable real-time data. By integrating ultra-thin, flexible CurveSYS™ sensor foils directly into the load paths, A/B/C-pillars, and crash structures, the chassis becomes the vehicle’s digital nervous system.

Why do conventional sensors fail at critical moments?

The Problem with the Status Quo

Most sensors measure too far from the actual point of impact. The result? Signal noise, delays caused by heavy mounts, and imprecise data exactly when milliseconds matter most.

The CurveSYS Solution:

Thanks to our extremely robust construction and strategic integration, we measure the impact energy exactly where the ‚event‘ occurs.

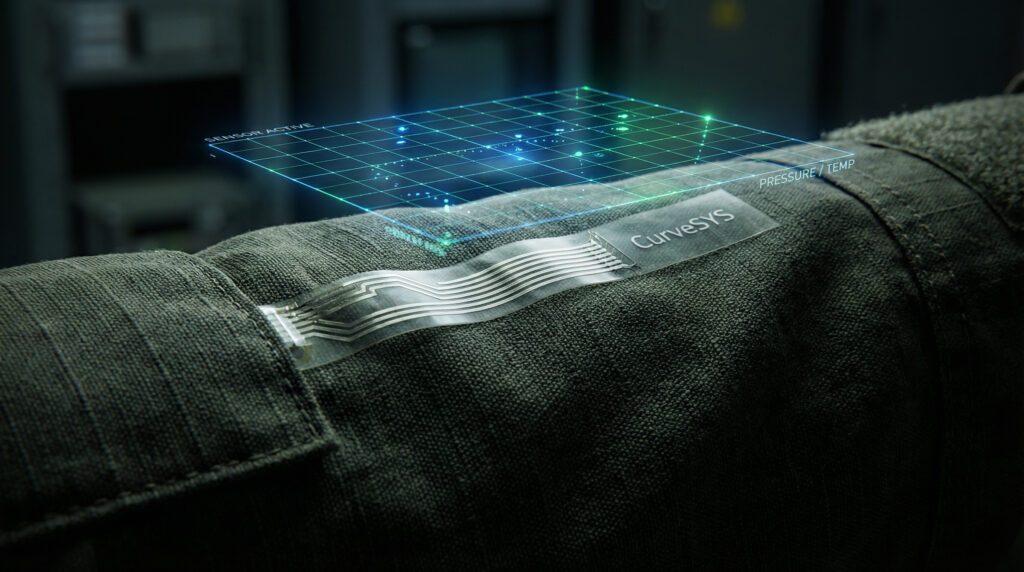

In Textiles: Intelligent protection that moves with you.

In Helmets: Direct measurement without the lag of external attachments.

In Vehicle Bodies: High-precision data acquisition from the core of the structure.

CurveSYS™ sensors are built on a modular architecture

This allows scalable sensing zones, adaptive sensitivity and seamless integration into existing systems.

→ Maintains signal stability under repeated stress

From signal to intelligence

Raw sensor signals are only the beginning.

CurveSYS focuses on intelligent evaluation logic that enables event classification, state detection and system-level decision support.

USE CASES:

• Impact detection

• Deformation Monitoring

• Interaction Recognition

Humanoid Robotics: The Sense of Touch

The Dual Power of CurveSYS™ Sensors

Robots no longer just move; they feel. Our Pressure Matrix allows humanoid hands to handle the most delicate objects with human-like sensitivity. In the defense sector, our Sensor Patches provide a digital nervous system for ballistic equipment, analyzing impact force and location in real-time to provide critical safety status updates.

• Precision Grip:

Dynamic force mapping for delicate object manipulation.

• Real-Time Haptics:

Instant feedback loops for advanced robotic dexterity

SMART Defense: Intelligent Protection

The Sense Of Data

In the security world, data is as critical as armor. Our CurveSYS™ Sensor Patches are integrated directly into ballistic equipment to provide a digital nervous system for the operator. In the event of an impact, the system instantly analyzes the force and location, providing a critical safety status to the tactical network.

Whether it’s giving a robot the ability to touch or a soldier the ability to monitor their safety status, CurveSYS™ provides the ultra-thin, flexible intelligence required for the future of humanoid and defense systems.